NdFeB magnets are widely quoted for their excellent magnetic energy and low price. Mainly used in electro-acoustic devices, components, instrument industry, automotive, nuclear magnetic resonance, magnetic therapy and other fields. It is very versatile.

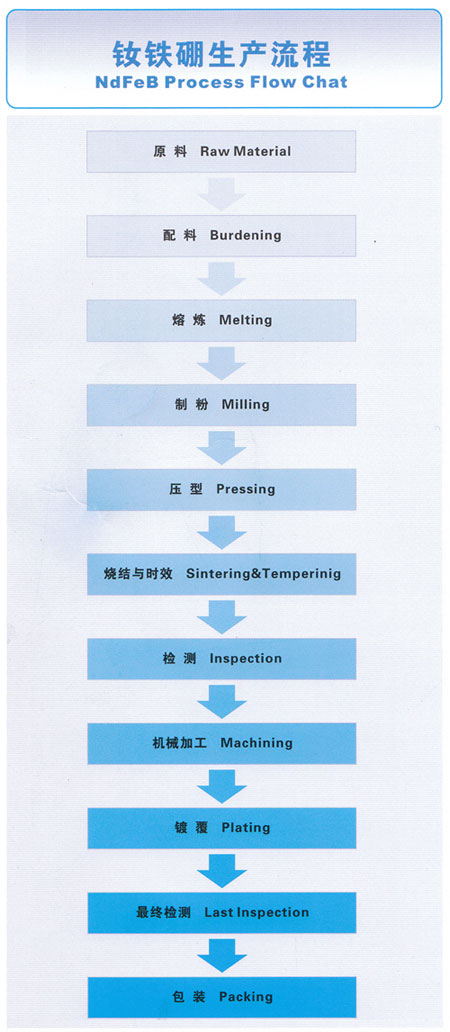

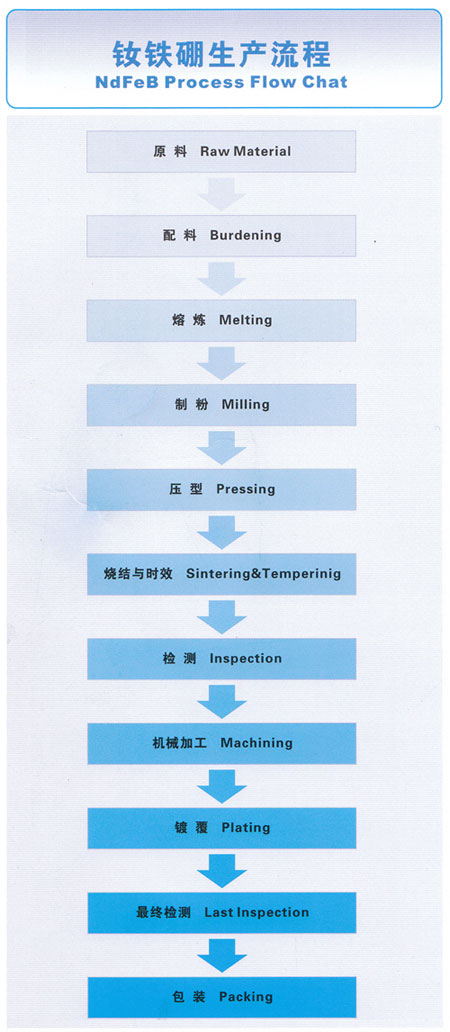

NdFeB magnets are a kind of strong magnetic material that does not demagnetize at normal temperature, so it is also called a permanent magnet. Its main production process is as follows:

Ingredients - smelting - powdering - pressing - sintering + tempering - magnetic testing - grinding - cutting - electroplating - finished products.

Heavy, through a series of processes of smelting, milling, pressing, sintering, tempering, to make the blank material, and then processing the produced cylindrical and square blanks, first of all, after polishing, why, because it is bought back The surface of the blank material is very rough and uneven. If it needs to be glued, the glue is very important. It is necessary to stick the magnet blank to the asbestos board, then stick the asbestos board to a fixture and stick it. Then put the clamp on the slicer and adjust it before you can start cutting.

Usually, a square magnet must be cut at least three times, that is, it needs to be glued three times, and each time it is cut, it needs to be boiled. The purpose is to cook the glue and make it easy to re-stick. After a square magnet is cut, chamfering is also required, because the cut angle of the magnet is very sharp, which is not conducive to electroplating and is not conducive to the safety of the product. After electroplating, the product is magnetized, tested, Packaging and shipping. Therefore, a small magnet seems to be very simple, and its production process is very troublesome. Some customers order it and it is unreasonable. According to our magnet processing technology, one product needs the fastest. Time can only be done well, and it is necessary to ignore the cost and ignore all the conditions to achieve this delivery period. The magnet seems to be simple, and its production and processing are more complicated.